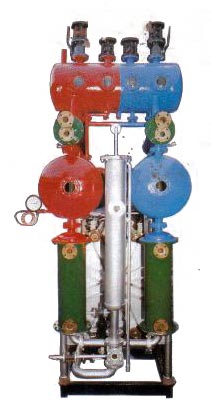

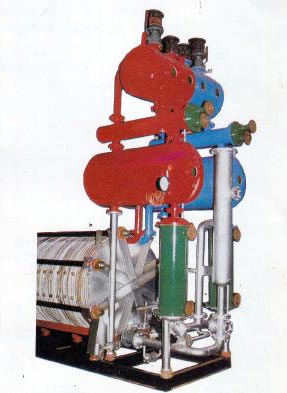

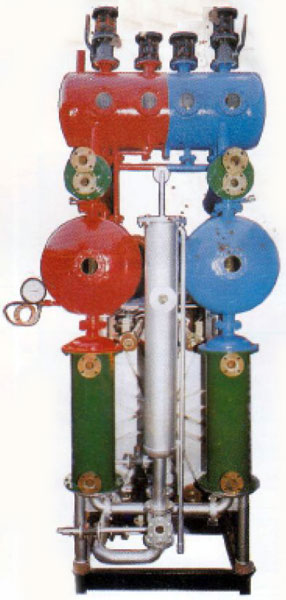

We are engaged to offer wide range of Water Electrolyser. These are available at market leading price e are very well familiar with varied industry requirements & application demands pertaining to our products and its appreciated by client. Filter press cells (BI- Polar) are structurally compact, having natural Electrolyte circulation and gas electrolyte separator outside the cell and have enhanced Space Time yields. We have fabricated and commissioned eleven numbers of Biopolar filter press cells. (Rectangular design) in Indian Market till 1988 end. These units are successfully operating, giving trouble free service to our esteemed customers. The designed of biopolar cell was developed indegenously and fabricated in our factory. We have wide experience, quality control, operation and maintanance of Biopolar Filter Press Cells.

Fundamental of Water Dissociation : The reaction for decomposition of water by means of passing current in a solution of HNO3, NaOH or KOH is a phenomenon observed by researcher, which is represented by the following equation.

- Cathode 2H2(I) + 2e = H2 (g) + 2OH (aq)

- Anode 2OH (aq) = 1/2O2 (g)

- Cell H2O (I) = H2 (g) + ��â�š���½ O2 (g)

Design

- The cell is in circular shape for uniform distance between Anode Cathode.

- The asbestos diaphragm is fixed on solid frames with bolting, which keeps the generated gases separate and maintain uniform purity.

- The frames, centre electrodes, End Electrodes, End Frames are fully machined from selected Steel and Nickel plated to have uniform pressure on each faces and gasket. Thus, the iron in electrolyte and leakage is fully controlled.

- The installation of Electrolyte separation tanks, Gas coolers and Gas washing tanks are arranged in such a manner that the cell can be attainded without dismentalling the complete plant.

- The +Ve (Anode) and -Ve (Cathode) connection are provided on top of cell to have minimum length. The filter provided will remove any fine fibres of asbestos, dust, rust and carbonate resistance to electricity and reduce efficincy. The plants are supplied with base frame and insulators ready to install without foundation.

Application of Hydrogen Gas

- Hydrogenation in production of sorbitol and mannitol

- Protective gas and reducing agent in the son ferrous industry

- Hydrogenation in the edible oil and margarine industry

- Cooling agent for turbo-generators in power stations

- Filling gas for meteorological ballons

- Gas for welding and cutting

- Synthesis gas for ammonia synthesis in the chemical industry

- Manufacturer of semicondutor

Purity of Gases

- Hydrogen 99.8 + 0.2 by Vol.

- Oxygen 99.5 + 0.5 by Vol.

Gas Pressure : Max. 250 mm of water column which is sufficient for storage in low pressure Gas Holders. When Oxygen is not required to store in gas holder it is vented through pressure balancing tank to atmosphere. Uses : The gases generated by these cells can be compressed to desired pressure for use in any chemical process.

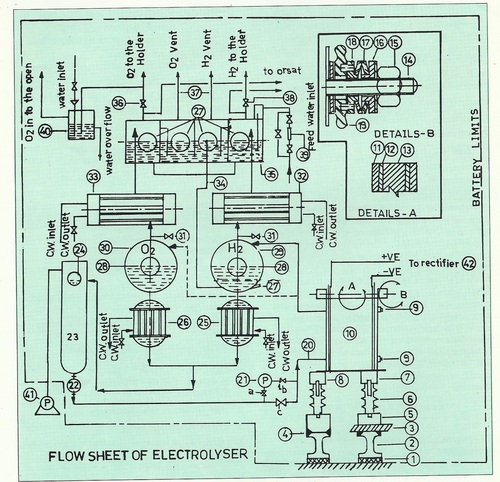

Flow Sheet of Electrolyser

| Type |

Hydrogen NM3/Hr. |

Oxygen NM3/Hr. |

No. of cell |

Max Dc. current design |

Dc volt regulation for rectifier |

Length of cell MM |

Breadth of cell MM |

Height of cell MM |

Total weight Kgs. |

Requried Electrolyte 25.1% |

| VE : 1000:20 |

20 |

10 |

54 |

1000 |

17-130 |

3500 |

1450 |

4125 |

8100 |

1300 |

| VE : 1000:25 |

25 |

12.5 |

67 |

1000 |

90-150 |

3900 |

1450 |

4125 |

9000 |

1500 |

| VE : 1000:25 |

25 |

12.5 |

34 |

2000 |

40-80 |

2900 |

1600 |

4450 |

8730 |

1800 |

| VE : 1000:30 |

30 |

15 |

41 |

2000 |

50-100 |

3000 |

1600 |

4450 |

9900 |

2000 |

| VE : 1000:35 |

35 |

17.5 |

47 |

2000 |

60-120 |

3300 |

1600 |

4450 |

10800 |

2200 |

| VE : 1000:40 |

40 |

20 |

54 |

2000 |

70-130 |

3500 |

1600 |

4450 |

11700 |

2500 |

| VE : 1000:50 |

50 |

25 |

67 |

2000 |

90-150 |

4800 |

1600 |

4450 |

13500 |

2900 |

To enquire about the desired product(s), just check the box and then click “Inquiry Now” button which is provided below.